How to Choose Your Bottom Bracket Bearing

The ABEC scale is an industry-accepted standard for the tolerances of a ball bearing. It was developed by the Annular Bearing Engineering Committee (ABEC) of the American Bearing Manufacturers Association (ABMA). The ABEC scale is designed to provide bearing manufacturers dimensional specifications that meet the precision bearings standards in a specified class. Manufacturers who produce equipment that requires bearings must also know the dimensional tolerances to design parts that will accommodate a bearing.

ABEC ratings (Annular Bearing Engineer’s Committee) are standards to which each bearing must pass many tests to meet the scheduled requirements, including noise testing at high RPM, extremely tight tolerances for the internal diameter, outer diameter, the roundness of the ball, trueness of races, and surface finish for all of the above.

There are five classes from largest to smallest tolerances: 1, 3, 5, 7, 9. The higher ABEC classes provide better precision, efficiency, and the possibility of greater speed capabilities.

The scale also works as a guide for consumers to make informed decisions about the type of bearing they desire, despite not knowing factors related to materials, manufacturing, and performance.

High-rated bearings are intended for precision applications like aircraft instruments or surgical equipment. Lower graded bearings are intended for the vast majority of applications such as vehicles, mechanical hobbies, skates, skateboards, fishing reels, and industrial machinery. High ABEC-rated bearings allow optimal performance of critical applications requiring very high RPM and smooth operation.

ABEC 3 Bearings

Grade 10 Chromium steels balls are 10/1,000,000 round, twice as round as the industry standard at it’s highest level.

ABEC 5 Bearings

Grade 5 Chromium steels balls are 5/1,000,000 round, this is considered military grade level specification, used for precision equipment.

MAX Bearings

Designed specifically for suspension pivots, Enduro Bearings pioneered MAX-type bearings almost 20 years ago for bicycles to address the challenges associated with mountain bike pivots. These bearings have 35-40% more load capacity than standard radial bearings.

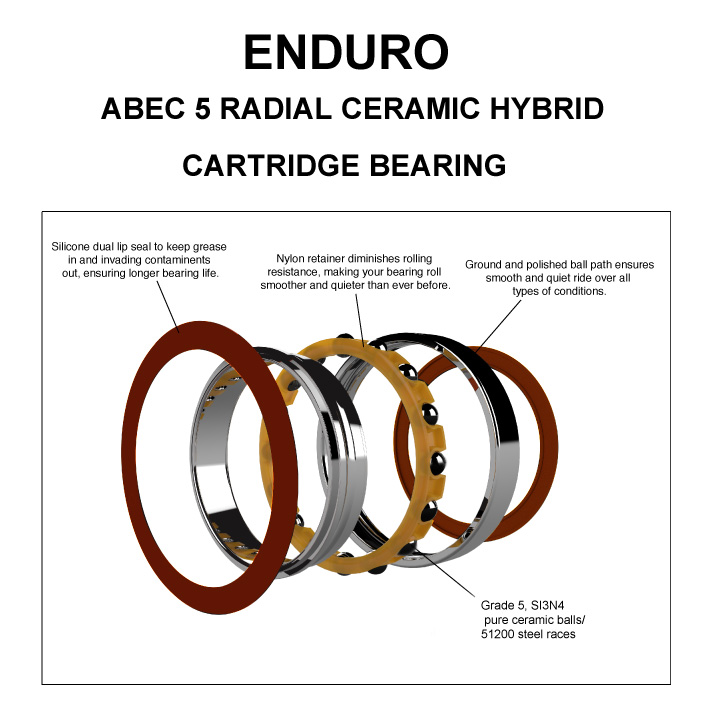

Ceramic Hybrid (CH) ABEC-5 Grade

Ceramic bearings are not only here to stay. They are now the standard, period. When carbon fiber was first introduced, many riders were still on steel bikes in the Tour de France, but now every racing bike is made of carbon fiber.

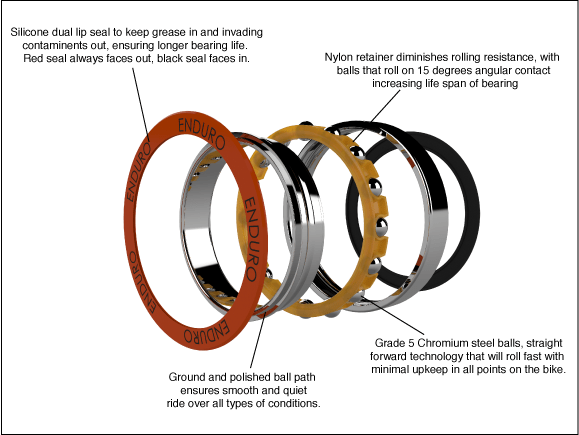

Angular Contact (A/C)

For the ultimate bottom bracket bearings, and for many hubs, these are the best bearings available for speed, balance, and longevity. Because they utilize a large surface area design, the load from all the balls is shared equally at all times, spinning faster than any radial bearing where only 30% of the balls may be taking the load.

ZERØ Ceramic Bearings

Proven time and again in World Cup race conditions, the ZERØ Ceramic bearings are the ultimate race day weapon. Oversized Grade 3 balls roll on races which are ground to a mirror finish after receiving Magnetite and then Cryogenic treatments for hardness and longevity.

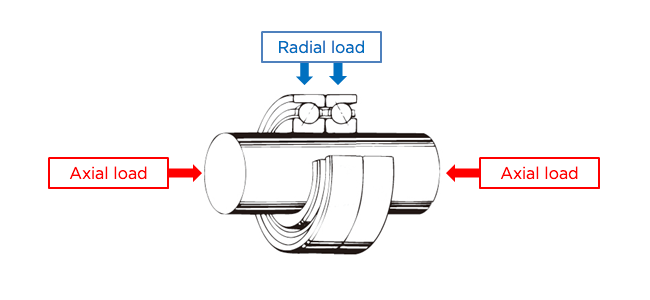

Dual Row Flanged

Why Dual Row Bearings? Hard cranking applies a heavy axial load from both directions, you can use a double-row bearing to transfer energy to rotation and not load. In the picture of the shaft above and we have a ball bearing, and the radial load is the load that’s perpendicular to the shift. So it doesn’t matter if the shaft is going towards vertical. The radial load will always be perpendicular to the actions of the shaft. The axial load and the thrust load will be parallel to the axis. And if you ever combine those situations, then you can have both radial and axial.

Expand your choice of cranks for use in frames with 41mm ID shells. Replace your bottom bracket with these dual-row flanged bearings that come in 29mm and 30mm to fit directly into your frame. These bearings fit directly in frames with 41mm ID bottom bracket shells. Crankset spindle length must be longer than 104mm when used in an 86.5mm wide BB shell. Note: Dual Row bearings are 11mm deep while single-row bearings are 7mm. Check your frame shell to ensure the dual row bearing will fit. When installing bearing use the 42mm side of the Press 7 drift and not the 41mm. Using the 41mm can sheer off the retaining flange on the bearing.

Bearing Life

Wheels Manufacturing has performed real world testing in there labs to determine typical bottom brackets bearing mileage wear. Keep in mind we are in a lab without any environmental concerns like dust or moisture. Just miles. Research found.

OEM Bearings

Average lifespan 500 miles

ABEC 3 Bearings

Average lifespan 2000 miles

ABEC 5 Bearings

Average lifespan 2000 miles

Ceramic Hybrid (CH) ABEC-5 Grade

Average lifespan 5000 miles

Angular Contact (A/C)

Average lifespan 5000 miles

ZERØ Ceramic Bearings

Average lifespan 5000 miles

Types of Seals

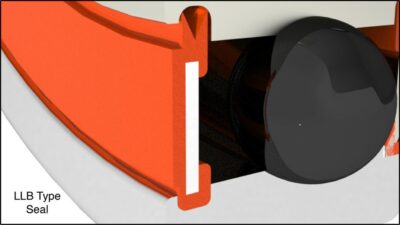

Enduro LLB Type Seals

Our most popular seal type is a Nitrile material rubber with a steel insert. Rather than the standard 2RS type seal, we go a step further by machining a groove into the inner race where the seal can rotate with better efficiency and less rolling resistance. Rather than one thick seal lip rubbing on a blunt surface, LLB type utilizes two razor-thin sealing lips riding in the groove with light contact. The outside lip keeps the water and contaminants out, while the inner seal retains the grease for smooth function and long intervals between servicing.

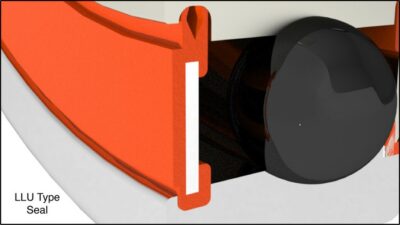

Enduro LLU Type Seals

Similar to the LLB type seal, LLU is a full-contact, dual lip seal riding in a groove on the inner race. With more sealing pressure, these are ideal for pivots or headsets that continually come in contact with dirt, sweat, and dust. The increased seal pressure and 2 lips help retain the 90% grease fill we use on these bearings to better displace any moisture and continually lubricate the balls and races.

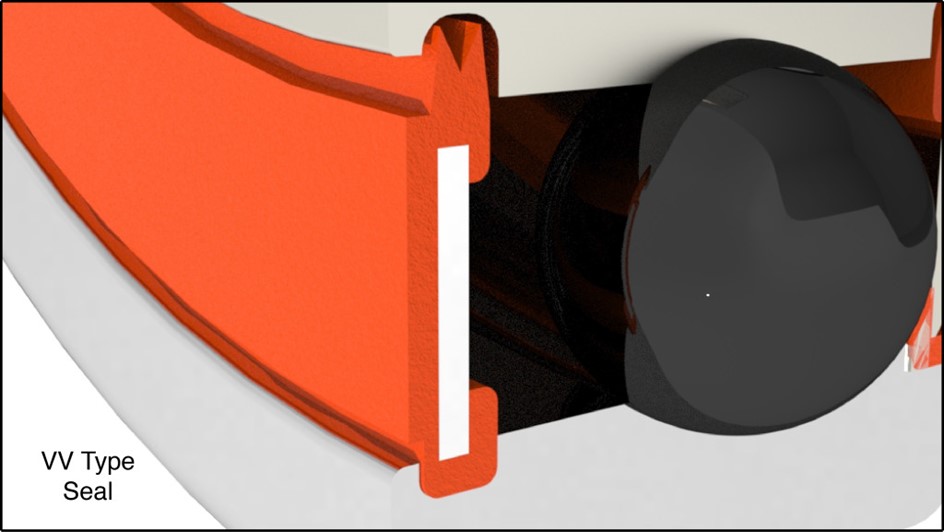

Enduro VV Type Seals

Developed with the idea of rolling as fast as possible, this dual lip configuration does not make contact with the bottom of the machined groove. Since these bearings also have a high rate of grease fill, the grease migrates to the bottom of the groove where a hydromatic type seal is established between the 2 lips and the grease in the groove. This grease barrier keeps the dirt and contaminants from coming inside the bearing, while still rolling smoothly and with the least resistance of all our bearings.

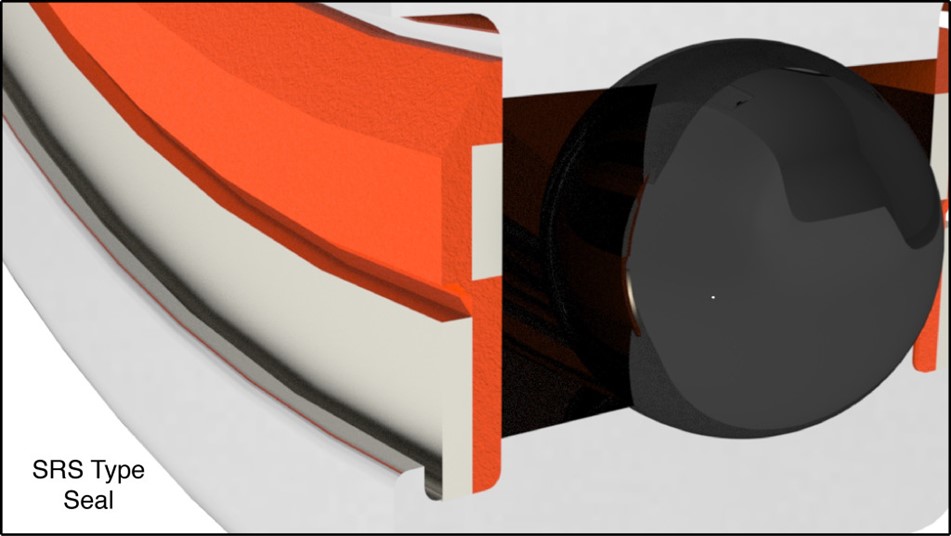

Enduro SRS Type Seals

Featured on many of our ABEC 5 level bearings, these seals employ a snap ring that can be removed with a small knife for quick and easy servicing. These seals can be removed with no danger of bending them while performing lubrication service, ensuring they will spin as smoothly after. The single sealing lip makes contact on a step machined into the inner race and sealing as an axial face seal. This type of seal configuration has extremely low rolling resistance and speed while being an effective barrier against dirt and water.

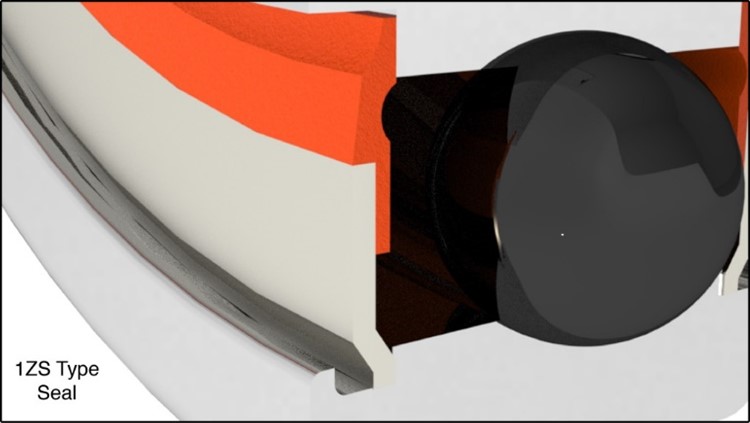

Enduro 1ZS Type Seals

Developed for Greaseable Bearing systems mostly found on suspension bikes, these bearings are completely open on one side where the grease is delivered during service by a pump through a grease fitting. As the old grease is displaced, it is purged past the inside seal lip of our specially designed “Seal-Shield”. This Seal-Shield will not pop off from the grease pressure but remains in place as the old grease passes past the sealing lip and is refilled with fresh grease.

Bearing Service

Important

Bearings can be serviced without removing from the cups. However, it is often easier to get a more thorough service completed with bearings removed from cups.

Angular Contact bearings are direction specific and come with two different color seals! Mark your bearings to note which side takes the black seal.

Lift up seal using a utility knife or pick. If servicing bearings outside of BB cups, remove both seals.

Clean seals and set aside. For Angular Contact bearings, note which side takes the black seal.

Flush out old grease with a de-greaser. Dry bearing to remove any traces of degreaser.

Lightly press seals onto bearing. Seals should sit

flush to the outer face of the bearing races.